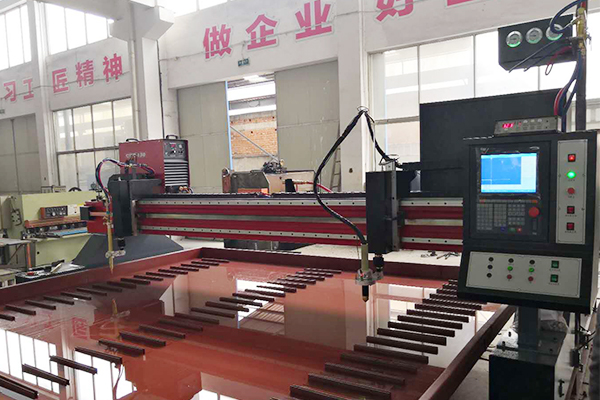

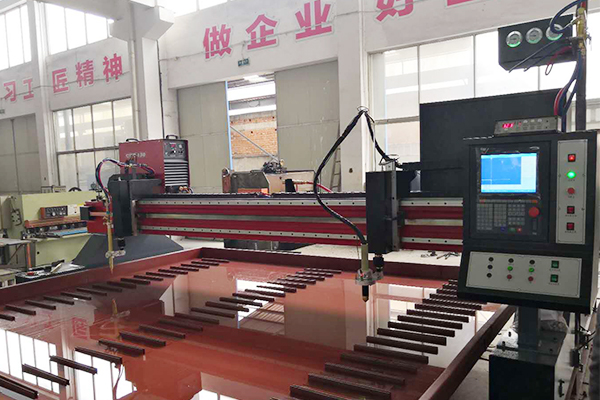

CNC cutting machine for steel plate cutting work is important, but it also needs our care, also need regular maintenance. CNC cutting machine maintenance, according to the amount of use to do maintenance. Here to give you a detailed description of the next maintenance methods: after 650 hours of operation of the machine tool, to do maintenance, manual operation is OK.

After cutting off the power supply, wipe the surface of the equipment with a semi dry cloth to ensure that the equipment is clean free of oil stains. When wiping, pay attention to whether there are defective screws nuts so that they can be filled in time. Check clean up the air circuit replace the "retired" trachea. timely replace the backfire filter element to ensure the smooth gas path. Adjust the tightness of cutting torch to make it reach the tightness of normal operation, check the wear of steel strip adjust the tightness.

When cleaning the cutting torch bearing, screw nut four cylinders, add grease, clean the gearbox add grease to ensure the normal operation of the machine. Use compressed air to clear the dust in the electrical box, check fasten the grounding device limit protection device. Secondly, its maintenance is about 5500 hours.

Mainly maintenance workers, in addition to maintenance, should also do: repair the old shield drag chain other accessories make up for falling paint, check adjust the instruments valves, repair return the damaged parts, check the wear of transmission mechanism components cutting torch bearings, timely handle if necessary.

The machine running for a long time will also affect the accuracy. It is necessary to correct the parallelism of the guide rail, adjust the symmetry of the wheel base equipment check. the perspective of production efficiency, the cutting speed depends on the plate thickness, cutting nozzle model, oxygen purity, gas quality other factors. The moving speed of the equipment should meet adapt to the requirements of the cutting process. In other words, the cutting efficiency has no direct relationship with the equipment itself.