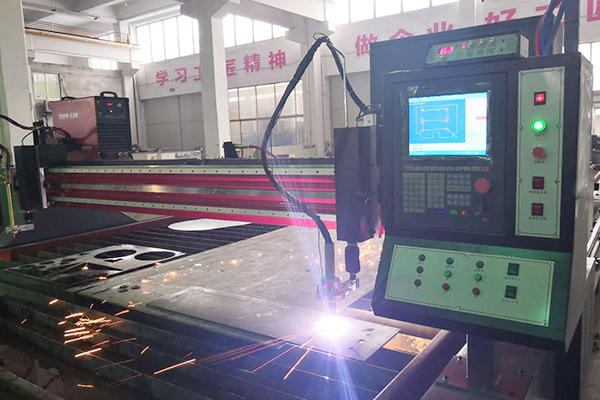

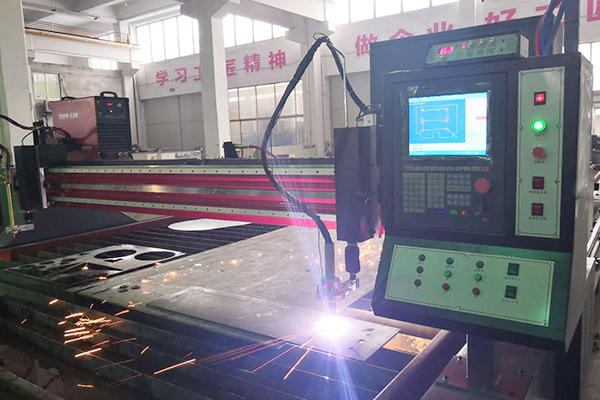

Due to the characteristics of high seam finish wide range of application of NC plasma cutting machine, NC plasma cutting has been used in machinery, shipbuilding, steel structure, automobile, easy pressure other industries, is gradually replacing the leading position of flame cutting in a certain field. Plasma cutting machine as a mechanical instrument, as well as cutting product accuracy requirements, the operation of plasma cutting machine has a lot of attention, need operator attention. NC plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to make the metal melt ( evaporate) at the incision of workpiece, remove the molten metal by the momentum of high-speed plasma to form the incision.

CNC plasma cutting machine can only be used as a conductor of metal, low carbon steel, aluminum stainless steel are typical examples. When cutting low carbon steel, operators will experience high speed deep cutting effect. Flame gas cutting cuts metal by burning at high temperatures by oxidation. Therefore, its application scope is limited to this kind of ferrous metal which can be treated by oxidation technology. Metals such as aluminum stainless steel form oxides that restrict further oxidation. This makes it impossible for traditional flame gas cutting to deal with this kind of material.

Plasma cutting, independent of oxidation treatment, can cut aluminum, steel other conductive metals. different kinds of gases can be used in plasma cutting. At present, most people use compressed air for plasma cutting. Air compressors are available in most cities. Therefore, the plasma cutting does need combustible gas compressed oxygen as the operating gas. When cutting thick plate, plasma cutting is more than flame gas cutting, flame gas cutting does need to link power supply compressed air, which is easy for some users to use.

Flame gas cutting is faster than plasma cutting when cutting thick steel, but the cutting speed of CNC plasma cutting machine is much faster than flame cutting when cutting thin plate, the efficiency is high. CNC plasma cutting machine is an ideal cutting method for cutting steel nonferrous metals with thick bottom less than 1 inch. Flame gas cutting requires operators to control cutting speed carefully to maintain oxidation treatment. Numerical control plasma cutting machine in this respect more flexibility.

For example, cutting sheet metal, which can be achieved with flame gas cutting. In addition, compared with mechanical cutting mode, the speed of CNC plasma cutting machine is much faster, it is easy to carry out nonlinear cutting. Cutting aluminum, copper, stainless steel other metal materials is the strength of CNC plasma cutting machine!